Shandong Dongheng Sinofibre New Materials Co., Ltd. was established in December 2018 and is located in Dongying, Shandong, the central city of the Yellow River Delta. It is a high-tech enterprise dedicated to the research and development, production, and sales of high-performance alumina fibers and related products.

Our main products include short alumina fibers, continuous alumina fibers, and fiber product series.

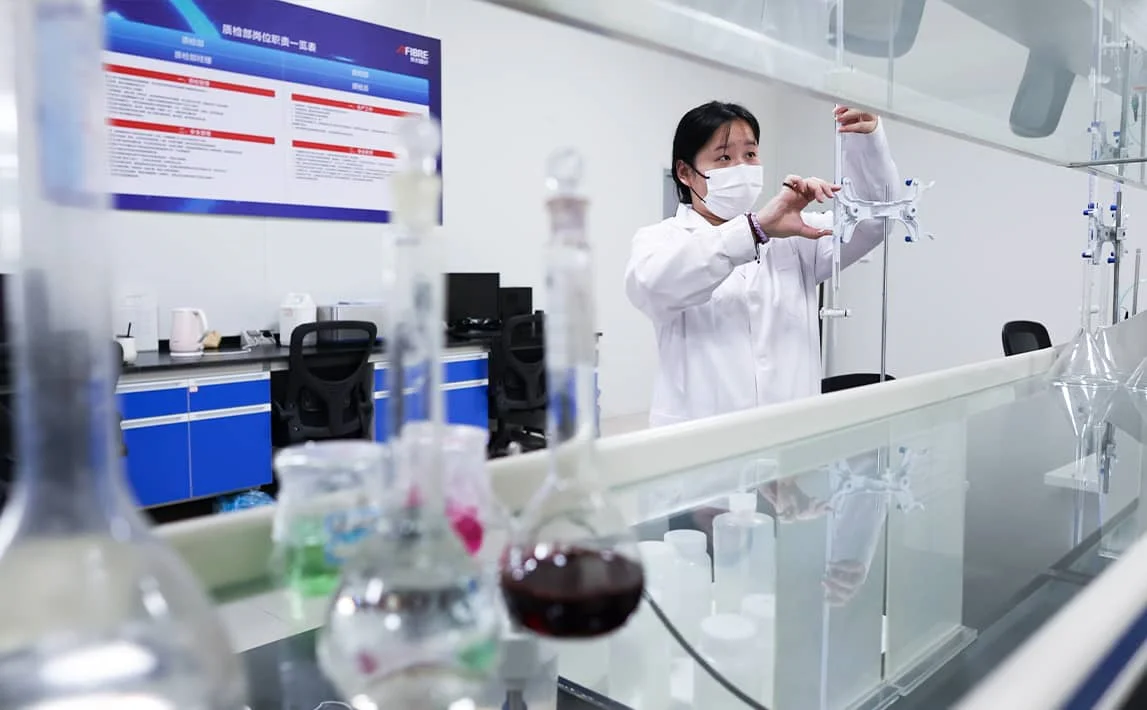

The project products are produced by the internationally leading "sol gel" preparation process. The company has full independent intellectual property rights of this technology, and its core technology cannot be copied. It is the first enterprise in China to industrialize the production of alumina fiber.

The company has been awarded honorary titles such as "High tech Enterprise", "Innovative Small and Medium sized Enterprise of Shandong Province in 2022", "Leading Enterprise of New Materials in Shandong Province in 2023", "Specialized, Refined, Unique and New Small and Medium sized Enterprise of Shandong Province", and "Demonstration Enterprise of Dongying City's Four New Economy".

We have successively undertaken the construction of research and development platforms for "Dongying Key Insurance Room" and "Dongying One Enterprise One Technology Research and Development Center".

committed to providing advanced materials and product solutions to realize industry serving the country

to become a leading enterprise in the field of high-end alumina fibers and materials

With the "sol gel" preparation technology, the aluminum oxide content can be flexibly adjusted during the preparation process, up to 99%, so as to prepare high aluminum fibers required in high-accuracy and cutting-edge fields such as aerospace, with comprehensive product production capacity, customized production according to customer needs, and meet the application needs of different fields.

The raw material route is different from foreign products, its basic raw materials are strictly screened, and all of them have been localized, so the product cost advantage is outstanding.

High purity of polycrystalline alumina fiber: the purity of raw materials used is high, and it is easy to control the composition and structure of products.

Good uniformity of polycrystalline alumina fiber: each component in the raw material can be evenly mixed at the molecular or atomic level.

Low temperature of fibre preparation process: it can be formed at room temperature, and the sintering temperature of ceramic fibre is 300-500 ℃ lower than that of traditional preparation process.

During the preparation process, the alumina content can be flexibly adjusted, up to 99%, so that the high alumina fiber required by aerospace and other high-end fields can be prepared. It has a comprehensive product production capacity and can be customized according to customer needs to meet the application needs of different fields.

In terms of industrialization: the main equipment in each link of the production line is non-standard equipment. It mainly focuses on independent research and development and stereotyped transformation. It has a number of invention patents and software copyrights for core equipment. It has broken through the "sol-gel" technology equipment continuous and automatic production checkpoint, forming a standard industrialized central control operation procedure, and the 1000 ton scale industrialized operation is comparable to the international level.

Alumina Bulk Fiber

Alumina Continuous Fiber

Alumina Fiber Needled Blanket

Alumina Fiber Mat

Alumina Fiber Paper