Alumina continuous fiber is made of alumina and silica as the main component, and is prepared by sol-gel process. It can be used for high temperature above 1000℃ for a long time. It can be woven into soft fabric like fibre rope and fibre cloth. It can also be used for making many kinds of composite materials, and the form is convenient and flexible. It is an emerging high-tech industry and a variety of materials urgently needed in high-tech fields such as aviation, aerospace and new weapons for national defense.

According to the different alumina content, our product models are divided into: AF17, AF18 and AF19.

The service temperature of α-Al₂O₃ Fibre is up to 1600℃, and that of mullite fibre is up to 1400℃; After treatment with liquid nitrogen (- 196℃) for 24 hours, the strength did not decrease.

The resistance of alumina fibre decreases with the increase of temperature. Above 600℃, the resistance tends to be constant, The dielectric constant and dielectric loss of alumina fibre are basically stable at high temperature and are suitable for high temperature wave transmission materials.

Retention rate of fibre strength after soaking in 10% alkaline solution for 24 hours: NaOH -- 40%; KOH--65%; NH₄OH--95%; Retention rate of fibre strength after soaking in 10% acid solution for 24 hours: HCl -- 96%; H₂SO₄--95%; HNO₃--96%; H₃PO₄--95%.

At room temperature, alumina fibre can be bent 1400 times, After high temperature treatment at 1000 ℃, it can still be bent for 60 times.

The device made of alumina continuous fibre has a hot surface temperature of 800 ℃ and a cold surface temperature of 278 ℃; When the hot surface temperature is 1000 ℃, the cold surface temperature is 388 ℃.

By adjusting chemical composition and heat treatment process, products with different properties can be obtained to meet different application needs.

| Performance | AF17 | AF18 | AF19 |

|---|---|---|---|

| Chemical composition(wt.%) | 72 AI₂O₃+28 SiO₂ | 85 AI₂O₃+15 SiO₂ | ≥99 AI₂O₃ |

| Crystalline phase | γ-AI₂O₃,+Amorphous | α-AI₂O₃+Mullite | α-AI₂O₃ |

| Molten Point (℃) | 1800 | 1800 | 2000 |

| Continuous use temperature(℃) | ≥1200 | ≥1300 | ≥1100 |

| Monofilament diameter(μm) | 9-12 | 11-14 | 11-14 |

| Density (g/cm³) | 3.0 | 3.4 | 3.9 |

| Tex(g/1000m) | 67/ 200 | 100/167 | 100/167 |

| Monofilament tensile strength(MPa) | ≥2.0 | ≥2.0 | ≥3.0 |

| Monofilament tensile modulus(GPa) | ≥170 | ≥240 | ≥330 |

| Dielectric constant@9.5GHz | 3.2 | 3.8 | 4.7 |

| Loss tangent@9.5GHz | 0.005 | 0.005 | 0.007 |

|

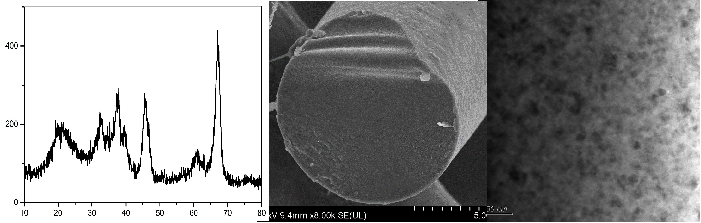

AF17 fiber The fiber is microcrystalline polycrystalline(γ-AI₂O₃+Amorphous), diameter 9-12μm. The tensile strength at room temperature can reach more than 2.0GPa, and the service temperature is more than 1200℃. It has good high temperature resistance and creep resistance. |

|

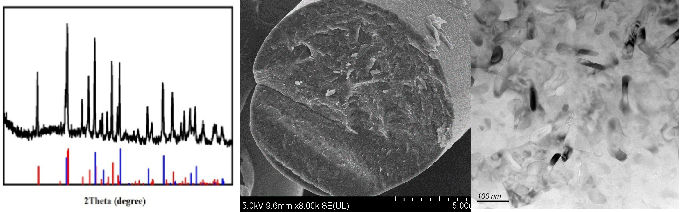

AF18 fiber The fiber is in micro crystalline state( α- AI₂O₃+ mullite), diameter 11-14μm. The tensile strength at room temperature can reach more than 2.0GPa, and the service temperature is more than 1300℃. At present, alumina fiber has the best creep resistance. Below 1100℃, the strength is basically unchanged. At 1200℃, more than 90% of the room temperature strength is retained, and at 1300℃, more than 80% of the room temperature strength is retained. |

|

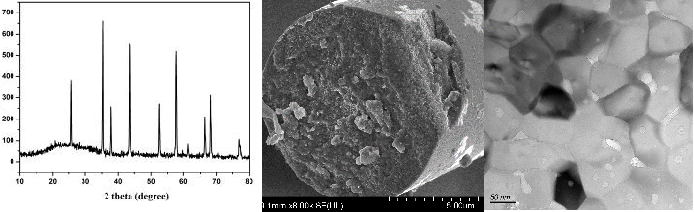

AF19 fiber The fiber is in micro crystalline state( α- AI₂O₃), diameter 11-14 μm. The tensile strength at room temperature can reach more than 3.0Gpa, and the service temperature is more than 1000℃. High strength at room temperature, good mechanical properties, can be used as composite reinforcement, but poor creep resistance at high temperature. |

*REQUIRED FIELDS