The alumina fiber mat is made of high alumina polycrystalline fiber (alumina fiber with a content of more than 72%), which is a kind of high-quality lightweight high-temperature resistant polycrystalline non expandable mat material. It has excellent aging durability, blowing corrosion resistance and ideal corrosion resistance, and the temperature resistance up to 1300 ℃.

Now it is widely used as automotive mounting mat of catalytic converter, and can adapt to various canning technologies currently used, and can provide customized design solutions. The company's products have passed IATF16949 quality system certification, European reach regulation certification and got SDS chemical safety manual.

According to the different standard areal density, the product models are divided into: DH100|1200、1300、1400、1500、1600、1700、1800、1900、2000、2100、2200、2250、2300、2400.

The mat is a non expandable mat with excellent bending performance, which is suitable for a variety of different canning process. The products can be used for most carriers, including diesel engine, gasoline engine, gas engine and other large-diameter, thin-walled even very thin-walled carriers.

PCW mat, alumina content ≥ 72%, good high temperature aging stability, and withstand temperature up to 1300℃, Low thermal conductivity, which can effectively prevent the shell of three-way catalytic converter from overheating.

Good corrosion resistance, excellent resistance to all chemicals except hydrogen fluoride, phosphoric acid and strong base. Blow erosion resistance loss ≤ 1%, which can withstand stronger airflow impact, ensure product performance, prevent waste gas leakage and product failure, and is applicable to national emission standard VI.

High friction coefficient and good stability, which can provide long-term stable and reliable physical support for all kinds of carriers, with higher safety performance.

It can be customized according to customer needs, with good flexibility and plasticity, and can adapt to various packaging technologies currently used.

| Nominal (g/m²) |

MIN Areal Density (g/m² ) |

MAX Areal Density (g/m²) |

Nominal (mm) |

Minimum (mm) |

Maximum (mm) |

GBD (g/cm³) |

Gap (mm) |

|---|---|---|---|---|---|---|---|

| 1200±10% | 1080 | 1320 | 8.5±0.9 | 7.6 | 9.4 | 0.35~0.55 | 2.2~3.4 |

| 1600±10% | 1440 | 1760 | 10.7±1.1 | 9.6 | 11.8 | 0.35~0.55 | 2.9~4.6 |

| 2250±10% | 2025 | 2475 | 14±1.6 | 12.4 | 15.6 | 0.35~0.55 | 4.5~7.5 |

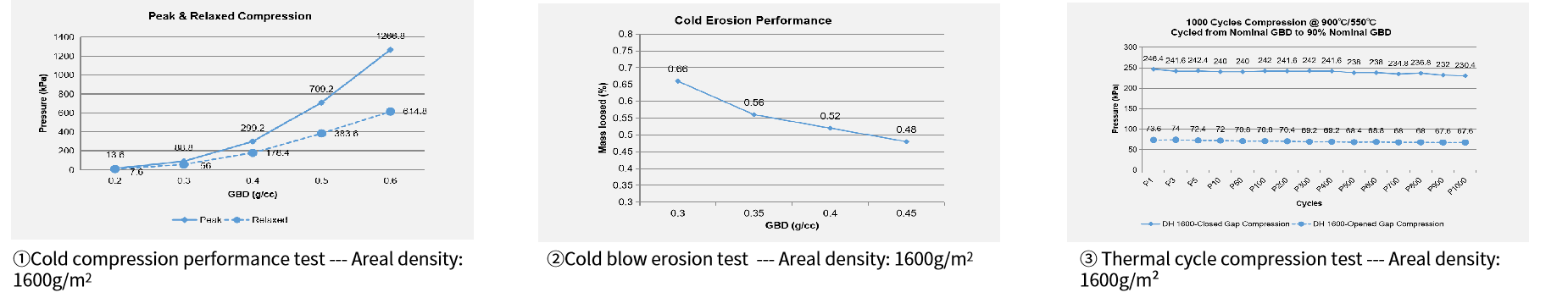

DH series mat are recommended to be canned with a gap bulk density (GBD) of 0.40g/cm3. The compression behavior of the mat at room temperature is shown in figure ①. Considering the strength of the substrate and the need for mat retention, users can choose the appropriate GBD according to the service environment.

DH series mat is made of high aluminum content fiber and has excellent wind erosion resistance. The mat has high corrosion resistance, which can effectively protect the safety of the carrier under various vehicle conditions and reduce the safety problems caused by operation and installation. The test data of simulated the mat canning section is shown in figure ②.

DH series mat has excellent temperature resistance and can withstand 1300℃ high temperature environment. As shown in figure ③, the aging resistance of the mat is tested by simulating the service environment of the mat. After 2000 cycles, the mat still maintains high elasticity and the pressure retention rate is more than 90%.

|

|

|

|

| Intelligent Thickness Gauge | Erosion Tester | Electronic Universal Tester | |

|

|

|

Aging Tester |

| Oven | Muffle Furnaces | Moisture analyzer |

*REQUIRED FIELDS