Alumina Fiber Blanket

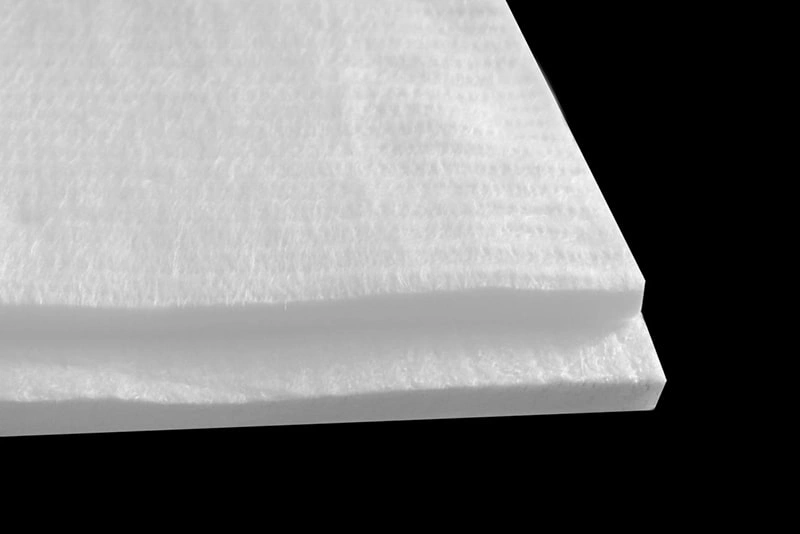

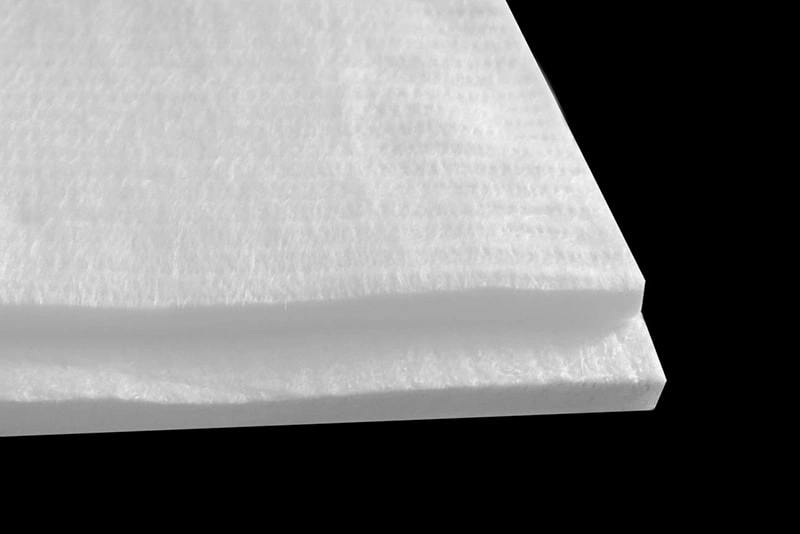

Shandong Dongheng Sinofibre New Material Co., Ltd. specializes in alumina fiber and fiber products. One of the company's popular products is 72-type alumina fiber blanket,belonging to the alumina-silica system, 72% alumina content with 28% silica content.

The alumina fiber blanket uses alumina fibers prepared by the "sol-gel" method as raw materials. The internal structure of the fibers is dense, and the crystal form is stable. After needle-punching treatment, the interweaving degree between fibers is improved, which gives it good anti-stratification ability, tensile strength and surface flatness. The alumina fiber blanket has excellent thermal insulation performance under high-temperature working conditions and can be used for a long time in relatively extreme environments.

Main Features of Alumina Fiber Blanket:

1. Excellent thermal stability , can be used for a long time at working conditions

above 1300 ℃ , up to 1600 ℃ ;

2. Acid and alkali resistance, with excellent resistance to other chemicals except

hydrogen fluoride, phosphoric acid and strong alkali;

3. Excellent tensile strength;

4. Excellent thermal insulation performance and low thermal conductivity ;

5. It has high friction coefficient and good stability, and can provide long-term

stable physical support for various carriers with higher safety factor.

The 72-type alumina fiber blanket has the characteristics of low density, low thermal conductivity, low thermal expansion coefficient, etc., as well as excellent high-temperature mechanical properties, chemical stability, electrical insulation, creep resistance and thermal shock resistance. Therefore, it has broad application prospects in high-temperature engineering fields such as ordnance, aerospace, and high-temperature protection fields such as industrial kiln linings.

Alumina Fiber Blanket Typical Technical Parameters

|

Serial Number |

Project |

Test Method |

Technical Indicators |

|||

|

1 |

Chemical Structure Al₂O₃ :SiO₂(%) |

GB/T 6900-2016 |

72:28 |

|||

|

2 |

Appearance |

GB/T 10220-2012 |

White, blanket-like, without defects or impurities |

|||

|

3 |

Mineral Structure |

XRD |

δ-Al₂O₃ /γ-Al₂O₃ /Mullite |

|||

|

4 |

Average Fiber Diameter (μm) |

GB/T 5480-2017 |

5~7 |

|||

|

5 |

Heating Permanent Line Change (%) |

GB/T 17911-2018 |

1400℃×24h<1% |

|||

|

1650℃×24h≤1% |

||||||

|

6 |

Thermal Conductivity (W/m ·k) ( Reference Value ) |

600℃ |

GB/T 17911-2018 |

BD=100kg/ m3 0.067 0.129 0.170 |

BD= 130kg/ m3 0.078 0.148 0.213 |

BD= 150kg/ m3 0.091 0.172 0.266 |

|

1000℃ |

||||||

|

1200℃ |

||||||

|

7 |

Tensile Strength (KPa) |

GB/T 17911-2018 |

BD= 100kg/ m3 ≥50 |

BD= 130kg/ m3 ≥70 |

BD= 150kg/ m3 ≥95 |

|

Alumina Fiber Blanket Product Matrix

|

Product Specifications |

Length/Meter |

Width/MM |

Thickness/MM |

Bulk Density Kg/M3 |

||||

|

Normal Value |

Limit Deviation |

Normal Value |

Limit Deviation |

Normal Value |

Limit Deviation |

Normal Value |

Limit Deviation |

|

|

72-3-100 |

7.2/10.8/14.4 |

0~4% |

610 |

597.8~634.4 |

3 |

2~4 |

100 |

85~114 |

|

72-3-128 |

7.2/10.8/14.4 |

610 |

3 |

2~4 |

128 |

113~147 |

||

|

72-3-150 |

7.2/10.8/14.4 |

610 |

3 |

2~4 |

150 |

135~175 |

||

|

72-5-100 |

7.2/10.8/14.4 |

610 |

5 |

3~7 |

100 |

85~114 |

||

|

72-5-128 |

7.2/10.8/14.4 |

610 |

5 |

3~7 |

128 |

113~147 |

||

|

72-5-150 |

7.2/10.8/14.4 |

610 |

5 |

3~7 |

150 |

135~175 |

||

|

72-6-100 |

7.2/10.8/14.4 |

610 |

6 |

4~8 |

100 |

85~114 |

||

|

72-6-128 |

7.2/10.8/14.4 |

610 |

6 |

4~8 |

128 |

113~147 |

||

|

72-6-150 |

7.2/10.8/14.4 |

610 |

6 |

4~8 |

150 |

135~175 |

||

|

72-7.5-100 |

7.2/10.8/14.4 |

610 |

7.5 |

5.5~9.5 |

100 |

85~114 |

||

|

72-7.5-128 |

7.2/10.8/14.4 |

610 |

7.5 |

5.5~9.5 |

128 |

113~147 |

||

|

72-7.5-150 |

7.2/10.8/14.4 |

610 |

7.5 |

5.5~9.5 |

150 |

135~175 |

||

|

72-8.5-100 |

7.2/10.8/14.4 |

610 |

8.5 |

6.5~10.5 |

100 |

85~114 |

||

|

72-8.5-128 |

7.2/10.8/14.4 |

610 |

8.5 |

6.5~10.5 |

128 |

113~147 |

||

|

72-8.5-150 |

7.2/10.8/14.4 |

610 |

8.5 |

6.5~10.5 |

150 |

135~175 |

||

|

72-10-100 |

7.2/10.8/14.4 |

610 |

10 |

8~12 |

100 |

85~114 |

||

|

72-10-128 |

7.2/10.8/14.4 |

610 |

10 |

8~12 |

128 |

113~147 |

||

|

72-10-150 |

7.2/10.8/14.4 |

610 |

10 |

8~12 |

150 |

135~175 |

||

|

72-12.5-100 |

7.2/10.8/14.4 |

610 |

12.5 |

10.5~16.5 |

100 |

85~114 |

||

|

72-12.5-128 |

7.2/10.8/14.4 |

610 |

12.5 |

10.5~16.5 |

128 |

113~147 |

||

|

72-12.5-150 |

7.2/10.8/14.4 |

610 |

12.5 |

10.5~16.5 |

150 |

135~175 |

||

|

72-20-100 |

3.6/7.2 |

610 |

20 |

18~24 |

100 |

85~114 |

||

|

72-20-128 |

3.6/7.2 |

610 |

20 |

18~24 |

128 |

113~147 |

||

|

72-25-100 |

3.6/7.2 |

610 |

25 |

23~29 |

100 |

85~114 |

||

|

72-25-128 |

3.6/7.2 |

610 |

25 |

23~29 |

128 |

113~147 |

||

Note:Other specifications of product indicators shall be deternined by agreement between the supply and demand parties.If there is no special agreement.The closest specification shall be matched in the matrix table.

Alumina Fiber Blanket Packing Specifications

|

Serial Number |

Packagig Materials |

Unit |

Configurationper Box Quantity |

Role and Function |

|

1 |

Carton |

Only |

1 |

Support products |

|

2 |

PE Bag |

Only |

1 |

Wrap the product, seal it against dust and moisture,and adhere to the inner wall of the carton |

|

3 |

Paper Separator |

Open |

2 |

Place it at the upper and lower ends of the carton toprevent the carton folding edge from rebounding and damaging the product. |

|

4 |

Desiccant |

Bag |

2 -6 |

Place in a PE bag to prevent moisture from entering the product during packaging |

|

5 |

Outer Box Label |

Open |

2 |

Posted on the symmetrical side of the outer box for easy identification and product collection |

|

6 |

Sealing Tape |

Strip |

2 |

Sealing function on both sides of the carton |

|

7 |

Stretch Film |

/ |

1 |

Wrapped around the outside of the carton to prevent dust and moisture, and to strengthen the attachmentbetween cartons |

|

8 |

Shovel Board |

Only |

1 |

Wooden, supporting cartons, convenient for logistics and transportation |

|

9 |

Certificate |

Open |

1 |

Finished products are inspected and qualified, and the certificate is placed for distinction |

|

1 0 |

Packing Tape |

Strip |

6 |

Generally used for export products, fixing goods and pallets |

|

1 1 |

Honeycomb Panel |

Indivual |

1pc/tray |

Covering each support top for protection |

|

1 2 |

Corner Guard |

M |

Depends on the tray 6 ~ 10 |

Protect the corners ofthe carton |

Note: Packaging specifications can be agreed upon by both parties.